PRECISION MACHINING

EffeDi Meccanotek’s philosophy can be summarized in three simple words: Quality-Reliability-Competitiveness.

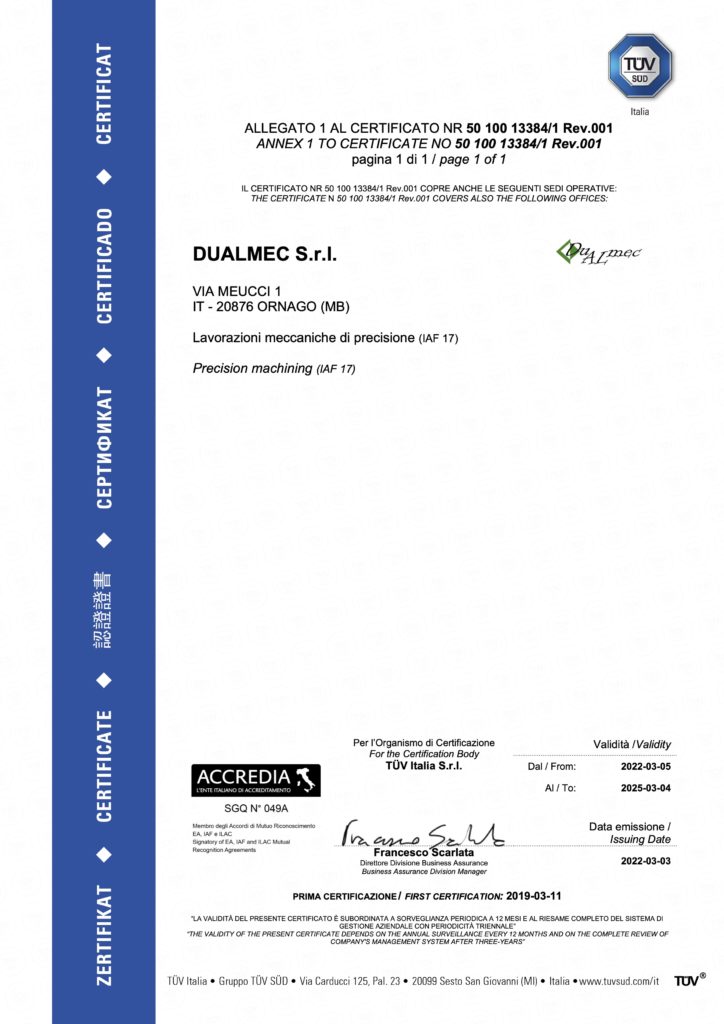

The quality of the products is guaranteed by a detailed control carried out initially at machine’s side and subsequently through motorized three-dimensional measuring systems. The Quality Office, inside the company, follows the production from the arrival of the raw material up to the final packaging, guaranteeing to the customer the best accuracy & safety thanks to the UNI EN ISO 9001:2015 certification.

Reliability is given by the synergy between the Duci brothers: mutual attention ensures that the products are monitored from the initial machining up to the last steps, ensuring high standards, absolute quality and short delivery times.

Competitiveness led EffeDi Meccanotek to stand out in several production sectors:

- Textile machinery

- Automotive

- Medical

- Agricultural

- Aerospace

- Oil and Gas

- Home automation

The significant investments in production units, human resources and the desire to implement the company business, led in 2007 to the opening of a separate production site in Monza Brianza, company Dualmec Srl specialized in aluminum extrusions machining with length up to 10500mm.

The current company structure allows EffeDi Meccanotek to provide a 360-degree service to its customer:

- feasibility study

- development of projects and drawings to create equipment

- planning

- mechanical processing with horizontal machining centers

- mechanical processing with vertical machining centers

- machining with multitasking lathes

- mechanical machining with numerically controlled lathes equipped with motorized tools and y axis

- surface finishes

- heat treatments (hardening, stress relieving, tempering, etc.)

- galvanic and coating treatments

- pre-assembled testing groups

- certifications